Material Data Sheet

Martensitic-Ferritic Stainless Steel - SM17CRS-125

SM17CRS-125 is a Martensitic – Ferritic stainless steel OCTG material referred to as “Super 17 Chrome”. This material was developed for HPHT flow wetted applications where high strength is a pre requisite. SM17CRS-125 is suitable for sweet environments with small amounts of H2S, under which standard Carbon and low alloy steels would suffer localized corrosion also called mesa or ringworm corrosion. “Super 17 Chrome” bridges the gap of performances between Martensitic and Duplex materials while expanding the application domain with regards to temperature, H2S content and Chloride concentration.

Diameters: 2-7/8” – 14"

Weights: as per API 5CT/ISO11960

Special application: Please contact Nippon Steel engineer, should You require specific size, weight, drift, or any other characterization.

- Proprietary SM17CRS-125. TGP-3121 (latest revision)

- API 5CT / ISO 11960

- API RP5C1/ISO 10405

- API 5CRA / ISO 13680

- VAM Book

- Nippon Steel storage & handling procedure for CRA materials

CO2 Corrosive well service, with temperatures up to 200 degC , including small amounts of H2S, and high Chloride content. Its primary function are Tubing and Liner applications, ie sections which are permanently exposed to production fluids.

SM17CRS-125 was developed for deeper HPHT wells thanks to its higher temperature threshold and increased Yield strength compared to SM13CrS110.

SM17CRS-125 is suitable for limited concentration of H2S, in combination with high content of Chloride with regards to SSC resistance.

SM17CRS-125 also features excellent localized corrosion resistance in high Chloride content environments while preserving excellent impact toughness.

Final material application will depend upon combination of CO2, H2S, Temperature, pH and expected Chlorides content. In addition, compatibility with packer & completion fluids (brines and additives) should be ascertained / verified in advance. For more detailed assessment please contact Nippon Steel engineers.

| PROCESS | DESCRIPTION |

|---|---|

| Steel making | Fine grained fully killed steel billets by the basic oxygen converter process or electric arc furnace process |

| Pipe making | Seamless |

| Heat treatment | Quenched and Tempered |

(mass %)

| C | Si | Mn | Cu | Ni | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| ≤ 0.03 | ≤ 0.50 | ≤ 0.50 | 2.0 ~ 3.0 | 4.0 ~ 5.5 | 16.0 ~ 18.0 | 2.0 ~ 3.0 | ≤ 0.10 |

| YIELD STRENGTH KSI |

TENSILE STRENGTH KSI |

ELONGATION % |

HARDNESS HRC |

TECHNICAL NOTE | |

|---|---|---|---|---|---|

| Min | Max | Min | Min | Max | |

| 125 | 145 | 130 | API Formula | 38.0 | - |

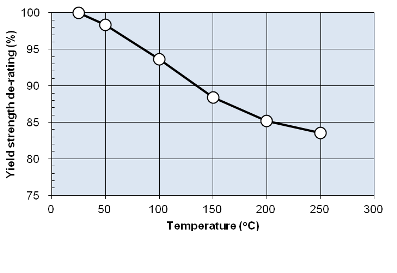

| UNIT | 25°C | 50°C | 100°C | 150°C | 200°C | 250°C | |

|---|---|---|---|---|---|---|---|

| Density | Kg/m3 | 7800 | 7790 | 7780 | 7770 | 7760 | 7740 |

| Young's modulus | GPa | 194 | 193 | 190 | 188 | 184 | 181 |

| Poisson's Ratio | - | 0.32 | 0.32 | 0.31 | 0.32 | 0.29 | 0.31 |

| Tensile strength de-rating | % | 100.0 | 98.1 | 92.8 | 89.2 | 86.4 | 84.8 |

| Yield strength de-rating | % | 100.0 | 98.3 | 93.6 | 88.4 | 85.2 | 83.5 |

| Thermal Diffusivity | x10-6 m2/s | 4.41 | 4.50 | 4.67 | 4.74 | 4.80 | 4.80 |

| Heat Capacity | x106 J/m3 deg.C | 3.44 | 3.54 | 3.67 | 3.84 | 4.03 | 4.23 |

| Thermal Conductivity | W/m deg.C | 15.2 | 16.0 | 17.1 | 18.2 | 19.3 | 20.3 |

| Specific Heat | J/Kg deg.C | 441 | 455 | 472 | 494 | 519 | 546 |

| Thermal expansion | x10-6 / deg.C | - | 11.0 | 11.0 | 11.1 | 11.2 | 11.4 |

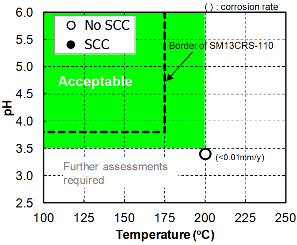

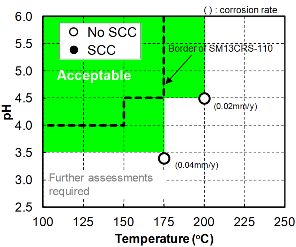

Figure 1 and 2 below compares the SCC resistance of SM17CRS-125 versus SM13CrS110. These SCC tests were conducted at elevated temperatures up to 200oC with 1,000mg/l Cl- for Fig 1 and 180,000mg/l Cl- for Fig 2. These 2 Chloride concentrations were selected to simulate condensed and formation water conditions respectively. SM17CRS-125 application limit largely exceeds SM13CrS110’s in terms of temperature and pH conditions.

|

|

| Fig.1 SCC test results of SM17CRS-125 4 point bent beam test, 1,000mg/l Cl- (0.17wt%NaCl), 100%AYS, 0.01barH2S+30barCO2 |

Fig.2 SCC test results of SM17CRS-125 |

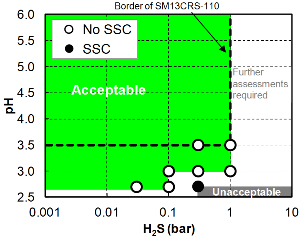

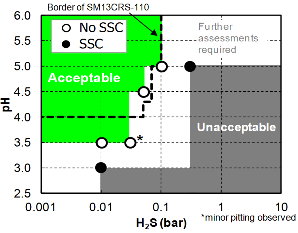

SSC susceptibility of SM17CRS-125 demonstrated using NACE method A test method is shown in below Figures 3 and 4. SM17CRS-125 survives lower pH condition than SM13CRS-110 in either conditions with low and heavy Cl- concentrations.

|

|

|

Fig.3 SSC test results of SM17CRS-125 |

Fig.4 SSC test results of SM17CRS-125 |

Health, Safety and Environment

While state-of-the-art HSE rules are applied throughout Nippon Steel manufacturing process, proprietary and specific HSE regulations shall be applied along the life cycle of the pipe until it reaches its final position in the well, according to each operator’s rules. This particularly applies to all phases of handling and transportation, assembly on the rig floor, and rig return if applicable. OCTG are heavy and by nature unstable. Special care shall be paid to potential risks of injury whenever handling OCTGs. Walking on pipes shall be avoided at all times. Usage of Personal Protection Equipments (PPE) is mandatory. Equipment and procedures will be established to capture the possible wastes generated during maintenance (cleaning, coating, doping) and disposed according to local regulations. This applies in particular to storage dope, running dope, or cleaning water wastes.

Best practices for transportation, handling and storage of OCTG in general are covered by ISO 10405 / API RP5C1. VAM Book is also a good source of handling practices for VAM connections. In addition to these general rules, specific care is recommended pertaining to SM13CRM, because improper handling could affect the material performances and by extension the corrosion resistance:

- Prevention of Spot Hardening

- Prevention of Iron contamination

- Adapted storage equipments and inspection practices, particularly in a wet and saline atmosphere

- Adapted running equipments and practices

- Prevention of corrosion on rig returns, particularly in presence of completion fluids

For more specific information please refer to Nippon Steel Storage and handling procedure for CRA materials or contact Nippon Steel engineers.