Manufacturing Process

Wakayama Works was established in 1942 and has become the integrated supply center for seamless pipes.

It is the company flagship to deliver Carbon steel, Low alloy steel and Martensitic stainless steel material. It hosts the unique and highly productive continuous process for medium size pipes including the innovative high toe-angle piercing technology.

Amagasaki Works was established in 1919 as the first integrated mill in Japan for the production of high quality seamless steel pipes and tubes.

Since then, the Works has specialized in high quality CRA cold drawn tubulars. It has been the leading manufacturing site of CRA OCTG to meet world-wide demand.

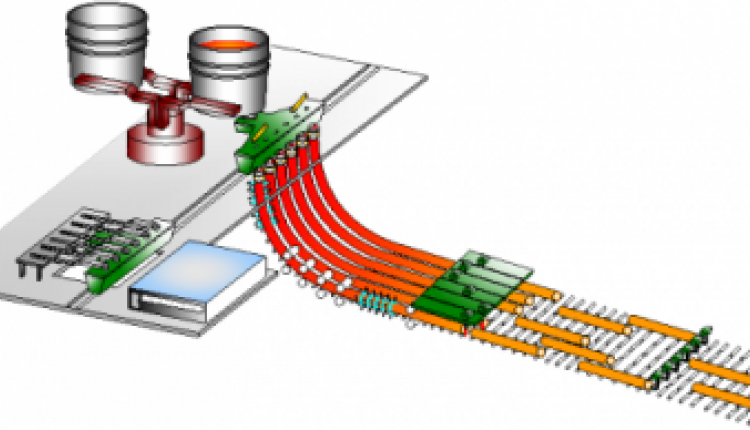

In continuous casting, Hot liquid metal is cast into solid semi-finished products in a variety of shapes.

Among these, round bar "Billet" is used for seamless pipe making.

Rectangular "Bloom" can also be used by applying a prior billet rolling process.

Nippon Steel fully computerized continuous casting achieves improved yield, quality, productivity and cost efficiency.

Billet Traceability to ladle is applied to maintain the best throughout quality control. Billet Traceability to ladle is applied to maintain the best throughout quality control.Billet Traceability to ladle is applied to maintain the best throughout quality control.Billet Traceability to ladle is applied to maintain the best throughout quality control.

- Billet Traceability to ladle is applied to maintain the best throughout quality control.

- Billet Traceability to ladle is applied to maintain the best throughout quality control.

Billet Traceability to ladle is applied to maintain the best throughout quality control.

- Billet Traceability to ladle is applied to maintain the best throughout quality control.

- Billet Traceability to ladle is applied to maintain the best throughout quality control.

Billet Traceability to ladle is applied to maintain the best throughout quality control.